- SERVICE

Get custom prototypes and low-volume production parts in as fast as 1 day

with our CNC machining, hot forging, precision casting, sheet metal fabrication and 3D printing services.

CLASSIFICATION

CNC MACHINING PARTS

China Qingdao ZH manufacturer OEM Custom Service hign precision cnc machining turning milling metal parts with ZH own anodized factory.

MORECNC MACHINING PARTS

China Qingdao ZH manufacturer OEM Custom Service hign precision cnc machining turning milling metal parts with ZH own anodized factory.

MORECNC MACHINING PARTS

China Qingdao ZH manufacturer OEM Custom Service hign precision cnc machining turning milling metal parts with ZH own anodized factory.

MORECNC MACHINING PARTS

China Qingdao ZH manufacturer OEM Custom Service hign precision cnc machining turning milling metal parts with ZH own anodized factory.

MORECNC MACHINING PARTS

China Qingdao ZH manufacturer OEM Custom Service hign precision cnc machining turning milling metal parts with ZH own anodized factory.

MORELooking for a reliable, quick-turn supplier of non-standard plastic and metal components?

Our incomparable in-house production capacity ensures your parts are delivered on-time in every single order. At Zehan factory, we have stable CNC machining facilities are designed for rapid prototyping, low-volume production and mass production of end-use components.

ZEHAN CNC MACHINING SERVICE

ZEHAN CNC MACHINING SERVICEWe have multiple CNC machining equipments and 3/4/5 axis machining centers for turning, milling, drilling, boring and tapping process with brass, aluminum, stainless steel, iron, plastic and titanium alloy and other materials. ZH can provide customers with a range of services from design, processing to surface treatment.

What is CNC Machining?

CNC machining refers to a machining method of controlling the displacement of parts and tools with digital information on a numerically controlled machine.

It is an effective way to solve the problems of various types of parts, small batch size, complex shape and high precision requirement, also helps to achieve high efficient and automated processing. We use CNC machining to not only manufacture parts and prototypes, but also to make mold tools that can be used in our hot forging and stamping services.

It is an effective way to solve the problems of various types of parts, small batch size, complex shape and high precision requirement, also helps to achieve high efficient and automated processing. We use CNC machining to not only manufacture parts and prototypes, but also to make mold tools that can be used in our hot forging and stamping services.

ZEHAN Hot forging service

ZEHAN Hot forging serviceZH has a complete hot forging production line, equipment forging capacity of 20T-3000T, and according to product design requirements, providing high-precision molds, can be used for metal forging of brass, steel, aluminum, stainless steel.

What is Hot Forging?

The forging process performed on the metal recrystallization temperature is named hot forging. Hot forging, also known as hot die forging, has a severe flow of deformed metal during forging, and the contact time between the forging and the mold is longer. Therefore, the mold material is required to have high thermal stability, high temperature strength and hardness, impact toughness, thermal fatigue resistance and wear resistance, and is easy to machine. Hot forging dies for lighter workloads can be made from low alloy steel.

ZEHAN stamping service

ZEHAN stamping serviceWhat is Stamping?

Stamping processing is the production technology of product parts with certain shape, dimension and performance by special stamping equipment, which directly deforms the sheet or strip in the mold.

ZEHAN Rapid Tooling service

ZEHAN Rapid Tooling serviceWhat is Rapid Tooling?

The development level of mold production is one of the important signs of the level of mechanical manufacturing. It mainly realizes the processing of the shape of the material through the change of the physical state of the formed material. It is known as the “mother of industry” and is widely used for punching and hot forging, stamping, precision casting, powder metallurgy parts pressing, pressure casting, and compression molding or injection molding of engineering plastic products. Zehan's mold engineers can design and manufacture high-precision molds according to the requirements of the products.

ZEHAN Surface Treatment Service

ZEHAN Surface Treatment ServiceWhat is Surface Treatment?

Surface Treatment is a process for artificially forming a surface layer different from the mechanical, physical and chemical properties of the substrate on the surface of the substrate, in order to meet the corrosion resistance, wear resistance, decoration or other special functional requirements of the product. Zehan Provides a variety of subsequent surface treatments that meet the performance requirements of the product.

ZEHAN Precision Casting Service

ZEHAN Precision Casting ServiceWhat is Precision Casting?

Precision Casting refers to the general term for the process of obtaining precision-sized castings. Compared with the traditional sand casting process, the castings obtained by precision casting have more precise dimensions and better surface finish. It includes: investment casting, ceramic casting, metal casting, pressure casting, lost foam casting.

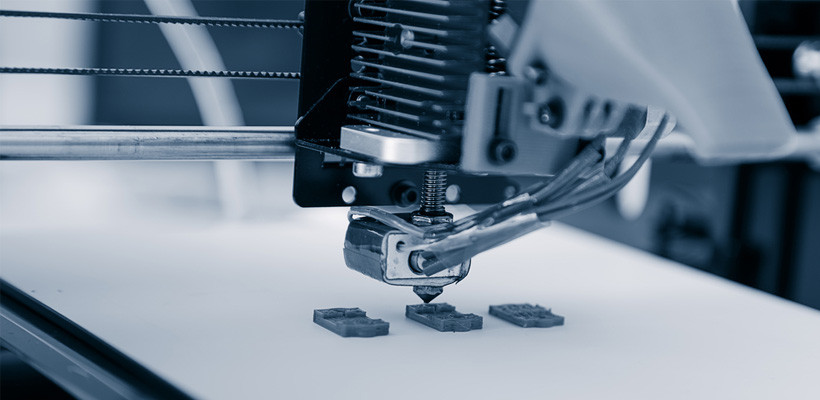

ZEHAN 3D Printing Service

ZEHAN 3D Printing ServiceWhat is 3D Printing?

3D printing is a kind of rapid prototyping technology, also known as additive manufacturing or laminated manufacturing. It refers to any process of printing a three-dimensional object. 3D printing is mainly a process of continuous addition and stacking raw materials under computer control. 3D printed content may be derived from 3D models or other electronic data. The printed 3D object can be any shape and with any geometric features. The 3D printer is also a kind of industrial robot. It is a technique to construct an object by layer-by-layer printing based on a digital model file and using an adhesive material such as powder metal or plastic.

ZEHAN Quality Inspection Service

ZEHAN Quality Inspection ServiceWhat is Quality Inspection?

3D printing is a kind of rapid prototyping technology, also known as additive manufacturing or laminated manufacturing. It refers to any process of printing a three-dimensional object. 3D printing is mainly a process of continuous addition and stacking raw materials under computer control. 3D printed content may be derived from 3D models or other electronic data. The printed 3D object can be any shape and with any geometric features. The 3D printer is also a kind of industrial robot. It is a technique to construct an object by layer-by-layer printing based on a digital model file and using an adhesive material such as powder metal or plastic.

- KEEP UP TO DATE

- Sign up for our newsletter and follow us on social media

subscription

NAVIGATION

LATEST POSTS

- Laser Cutting ServicesAug 16,2020

- What Is Metal Stamping?Aug 15,2020

- Sheet Metal Stamping ProcessAug 14,2020

ZEHAN MACHINERY

ZEHAN MACHINERY