- Quality Inspection Service

Raw material verification, quality inspection and testing

Manufacturing consistently high quality products requires good process control technology and advanced equipment. At Zehan, we have advanced inspection, measurement and testing equipment to verify that all incoming materials meet standards, and our QC department ensures that your parts meet your raw material drawing requirements. In addition, we ensure that each project follows the below steps to ensure quality:

How to Measure Accuracy of Metal & Plastic Parts?

Primary Measuring Tool

-

Caliper:

Caliper is a measuring tool used to measure length, inner and outer diameter, depth, and has the function of measurement and inspection.

-

Inner diameter micrometer:

Inside Micrometer for precision measurement of internal dimensions

-

OD micrometer:

Inside Micrometer for precision measurement of external dimensions

-

Height caliper

Is also known as height vernier caliper. The main purpose is to measure the height of the products, and is often used to measure shape and position tolerance.

-

Hardness tester:

It is one of the important performance indicators of metal materials

-

Ring gauge:

The ring gauge, also called the Correction ring gauge, it is a ring with specific size and property to correct the deficiencies of the measuring tools.

Advanced Inspection Equipment In-House

Infrared Spectrometer

The spectrometer is a necessary test instrument for our quality inspection department, which is used to identify the raw materials for storage. Using this tester, infrared radiation was used on the spectral band to verify 100% accuracy of the material.

-

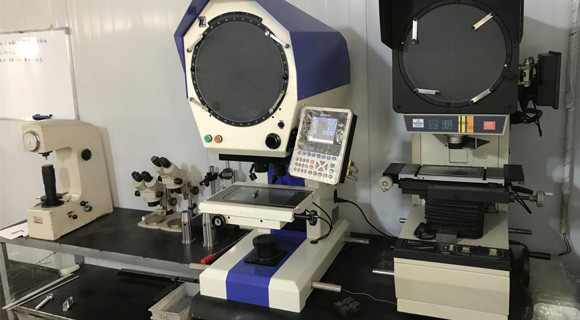

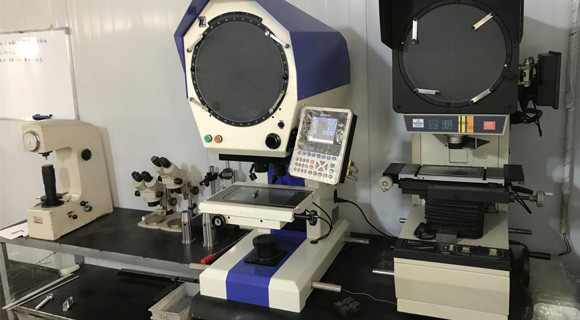

Profile Projector Machine

ZSM contour projector, ZSM contactless contour measuring instrument, contour measuring industrial microscope, laser scanner and multi-induction head coordinate measuring instrument etc. other manual and CNC control high precision measuring instruments.

-

Coordinate Measuring Machine

Coordinate Measuring Machine (CMM for short) is the most representative coordinate measuring instrument. In the coordinate measuring machine, the mechanical coordinate system is established by using the platform of the measuring instrument as a reference plane, the coordinate values of the measured points on the surface of the work piece to be measured are collected and projected into the space coordinate system to construct a spatial model of the work piece.

-

Roughness Tester

The roughness meter is widely used in the detection of various metal and non-metal processing surfaces. The instrument is a pocket-sized instrument integrated with the sensor host. It has a hand-held feature and is more suitable for use in the production field.

-

Visual Quality Standard

At Zehan, We have developed visual quality standards for our finishing services to check the painted surfaces and ensure the consistency of appearance. We also provide visual quality standards for metalworking services.

Certification

We are certified and meet the BV/SGS Assessment certificateISO 9001:2018, ISO 14001:2015 and BS OHSAS 18001:2007. This reflects our commitment to continuous improvement of quality and respect for our employees and the environment.

ZEHAN MACHINERY

ZEHAN MACHINERY