What is the Casting?

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process. Casting materials are usually metals or various time setting materials that cure after mixing two or more components together; examples are epoxy, concrete, plaster and clay. Casting is most often used for making complex shapes that would be otherwise difficult or uneconomical to make by other methods.Heavy equipment like machine tool beds,ship's propeller etc. can be cast easily in the required size rather than fabricating them by joining several small pieces.

Types

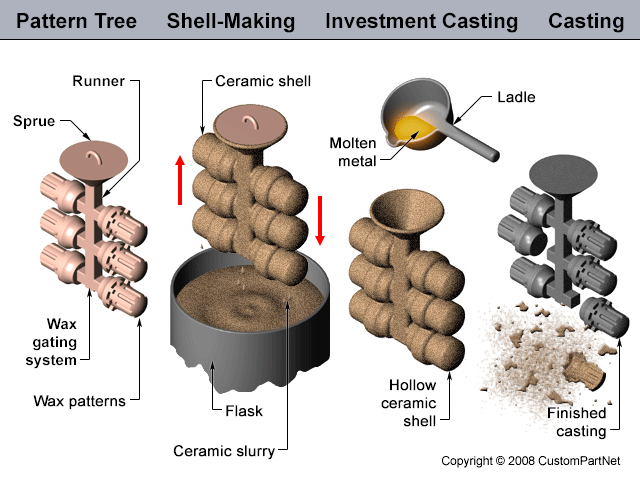

Casting (metalworking)

In metalworking, metal is heated until it becomes liquid and is then poured into a mold. The mold is a hollow cavity that includes the desired shape, but the mold also includes runners and risers that enable the metal to fill the mold. The mold and the metal are then cooled until the metal solidifies. The solidified part (the casting) is then recovered from the mold. Subsequent operations remove excess material caused by the casting process (such as the runners and risers).

Fettling

Raw castings often contain irregularities caused by seams and imperfections in the molds,as well as access ports for pouring material into the molds. The process of cutting, grinding, shaving or sanding away these unwanted bits is called "fettling".In modern times robotic processes have been developed to perform some of the more repetitive parts of the fettling process, but historically fettlers carried out this arduous work manually,and often in conditions dangerous to their health.

Fettling can add significantly to the cost of the resulting product, and designers of molds seek to minimize it through the shape of the mold, the material being cast, and sometimes by including decorative elements.

Casting process simulation

Casting process simulation uses numerical methods to calculate cast component quality considering mold filling, solidification and cooling, and provides a quantitative prediction of casting mechanical properties, thermal stresses and distortion. Simulation accurately describes a cast component's quality up-front before production starts. The casting rigging can be designed with respect to the required component properties. This has benefits beyond a reduction in pre-production sampling, as the precise layout of the complete casting system also leads to energy, material, and tooling savings.

The software supports the user in component design, the determination of melting practice and casting methoding through to pattern and mold making, heat treatment, and finishing. This saves costs along the entire casting manufacturing route.

ZEHAN MACHINERY

ZEHAN MACHINERY